Plastic PP PE PET Bottle waste recycling plant recycling production line Factory Supply New Technology Plastic Washing Machine For Hard Scrap Waste PP PE HDPE Milk Bottle Washing Line/Plastic Recycling Machine crusher shredder washing machine washer plastic recycling machine

Multilaminate waste plastic PP PE recycling plant

Product Description

PP PE hard plastic washing line

Plastic washing line is widely used to treat waste PP PE bottles, PP PE pipes, plastic barrels, sheets and other hard plastic. It is a crushing, washing, drying line. This production line is high automatic operating and save labor cost and low after maintenance. With advanced international industry concepts and technologies to meet waste plastic recycling at home or abroad. This film recycling machine could be displayed “L” or “U” shape according clients’ workshop.

Process:

Belt conveyor → Crusher (with water) → Three barrel friction washer →Float washing tank→→Float washing tank → Screw conveyor →Dewatering machine→Hot air drying system→Storage hopper→Control cabinet

Technical Parameters, for reference:

| Input capacity | 500kg/h | 1000kg/h | 2000kg/h |

| Workshop (m) | 35(L)*10(W)*6(H) | 45(L)*10(W)*6(H) | 55(L)*15(W)*6(H) |

| Ancillary staff | 4 persons | 6 persons | 8 persons |

| Installation power | 100kw | 160kw | 200kw |

| Water consumption | 2 t/h | 3 t/h | 4 t/h |

| Final product | 20mm Clean HDPE FlakesMoisture:max1%

Metal content: max20ppm Floatable contamination: less than 200ppm Total impurity: 250ppm |

||

Featured with:

a. We have the bale opening and feeding system which and equally feeding the material save labor.

b. Metal detector is optional for you which used to take out any kinds of metal from the plastic film.

c. Specially designed Film dewatering machine can make the best dehydration effect for film.

d. High speed dewatering machine and the drying system can guarantee the film flakes moisture <1%.

e. The fin dust separator machine will remove the final labels from the flakes to guarantee the PVC content.

Related Products

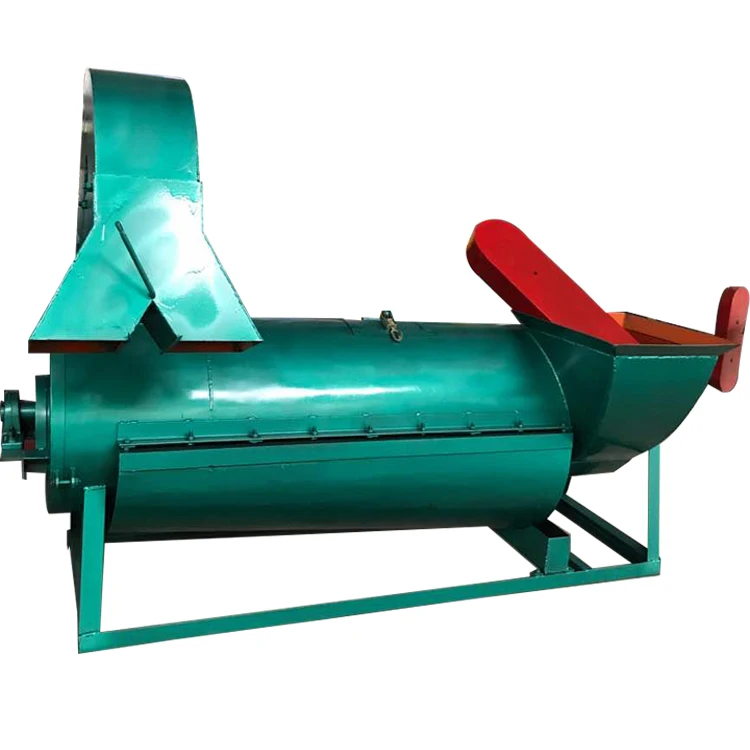

Feeding conveyor Hard plastic crusher machine

Float washing tank Horizontal dryer machine

PET bottle washing line

Taizhou Amige Machinery CO.,LTD

is an automated equipment manufacturer which develops, designs and produces products independently for 20 years already . With standard production plant, our factory covers an area of 15,000 square meters. The company has strong technical support, with 100 skilled technical staff, 20 technical design personnel.

Our main product is including plastic crusher,shredder,dryer,baler and Recycling washing line,Plastic pelletizing line etc. All kinds of plastic material can be cut and recycled by our machine. In addition, We are also committed to making dust treatment equipment and sewage treatment equipment.

We will put our best products recommended to more countries, and develop more distributors in many countries around the world. We are honored to with more international friends develop our glorious business.

Customers Feedback

Packaging & Shipping

Packing & Shipping

1)Packaging:

Whole film packaging machine; anti-collision package edge; fumigation-free plywood wooden box and pallets with iron binding belt.

2)Shipping:

We cooperate with SINOTRANS company whose experience in the ocean transportation will guarantee your machine safety. We also provide train transport, especially to Russia, Ukraine and other inland countries.

3)Payment:

We support T/T, L/C.

FAQ

1. How many days will it take for delivery?

R: 7 days if in stock, 30-45 days for new production.

2. What motor brand you use?

R: we use Wannan motor by default. Siemens motor available when required.

3. May I have video of machine performance?

R: Certainly, pls send us an inquiry, we will share video to you by email/whatsapp/wechat…

4. Are machines easy to install?

R: Yes, all of our machines are drive by motor. Pls place machines at horizontal first, after connected with electricity, it can work.

5. What are the spare parts?

R: Blade, bear, bearing, belt, screws.

6. How long can this machine use?

R: Above 5 years if you use daily.

7. What color can we choose?

R: Our machines generally do green, blue, white, as as request.

8. What incoterms do you accept?

R: FOB, CFR, CIF, FCA, EXW or as negotiation.

9. How to make payment to you?

R: by TT, LC, cash, or else.

Hot Tags: plastic equipment fully automatic waste hard plastic recycling washing line pp hdpe recycling machine customized factory, China [[productname] manufacturers, suppliers, factory